05 Duramax Cp3 Pump Lift Pump Bad Can I Just Use a New Lift Pump to Feed It

There are many great mysteries which have remained unsolved over the years, ranging from what's at the bottom of the Bermuda Triangle to what happened to D.B. Cooper and the money he took. While there have been several theories, to this day nobody knows the answer to either. One such automotive mystery was started in 2001, when GM introduced the Silverado HD's powered by the 6.6-liter Duramax diesel V8. It was a great powerplant and was the first of the big 3 to come equipped with common rail fuel injection, but there was one item missing which every other diesel pickup had before and since: a lift pump.

Diesel Fuel System Overview

There are many parts which make up the fuel system on a common rail diesel truck, and the path the fuel takes is like a choose your own adventure book; there are many different options. It all starts in the tank, which is where the fuel is stored whenever you fill up. Depending on the model, you might have between 25 and 40 gallons of capacity, and on most trucks there is a low-pressure fuel pump which sits inside the tank and pushes the fuel toward the engine at a relatively low pressure. Since diesel by nature is a dirty product, there is always at least one filter between the low-pressure pump and the engine to remove any dirt and contaminants, and likely there will be a water separator to remove any H2O which condenses in the tank. Next, the fuel enters the injection pump, where it can go one of two places: it either gets pressurized and sent to the rail or goes back to the tank in a return line. Most of the high pressure fuel inside the rail gets sent straight into the injectors, but there are some conditions like sudden deceleration or a drop in fuel demand which will cause a pressure relief valve to open up and send excess fuel from the rail back to the tank. Finally, once the pressurized fuel enters the injector, it either gets sprayed directly into the cylinder to make a big boom, or if there is extra, it flows back to the tank through the injector return to start its journey all over again.

Every one of those components can be found on just about every diesel pickup made in the US for at least the last 20 years, whether it's an HEUI Powerstroke, a 12-valve Cummins, or even the old 6.5 GM Diesels. But for some strange reason, the 6.6 Duramax came from the factory sans lift pump. The fuel takes the same path from the tank, through a filter, and into the injection pump, except now the CP3 is responsible for sucking fuel from the tank. This is true on every Duramax from the LB7 in 2001 to the LML in 2016. Interestingly enough, the 5.9 and 6.7 Cummins trucks which were equipped with an almost identical CP3 were equipped with a lift pump, and the newest L5P Duramax has one, all of which suggests a lift pump is an important part of a diesel fuel system. Yet the mystery remains, why didn't GM put one there in the first place.

You might be thinking to yourself, "wait a minute, LT… there are plenty of Duramax's on the road with well over 200,000 miles and no lift pump, and they don't seem to have any problems" and you would be partially right. If you have a stock truck with no desire to add horsepower, then sure, the engine can run fine without a lift pump for a long time. But just because it can doesn't mean it should. If you compare the CP3 in the Duramax to the CP3 in the Cummins, the one on the Duramax has to do a lot more work. Rather than having a constant supply of low pressure fuel at the inlet of the pump like on the Dodge, the GM CP3 is required to generate enough suction to draw fuel from the tank at the same time it has to raise the fuel to a maximum of 27,000 PSI. If that's not enough, the CP3 has at least 15 feet of line between itself and the fuel tank, with plenty of twists and turns which gives opportunity to create aeration in the fuel. Over time with the presence of vacuum, the rubber lines can actually collapse and cause a restriction, and if you add more horsepower, you increase the workload on the injection pump even more, and at a certain point, the CP3 simply can't keep up any more.

High Power Blues

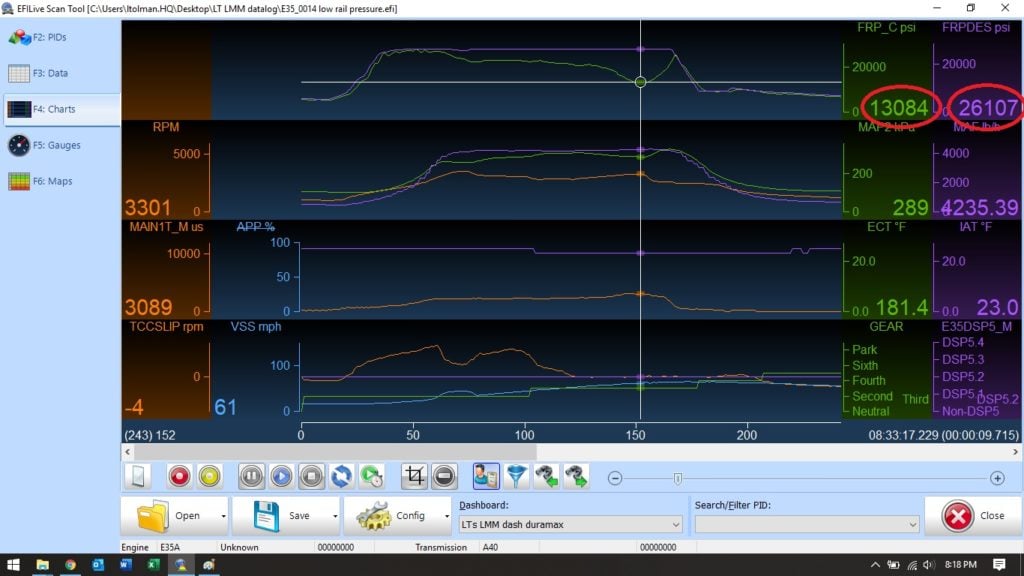

A well-documented problem on any Duramax whether it has the CP3 or 4, is a loss of rail pressure during acceleration once the truck has a higher power tune on it, and I have experienced this myself many times. It can happen when taking off from a light under medium throttle, flat footing the skinny pedal to pass the hay wagon taking up the whole lane, or on a sustained power run pulling a trailer up a steep grade. Things will be going along just fine, when suddenly it feels like you lifted your foot halfway off the go pedal. The rate of acceleration slows, and you might have a check engine light pop on with a P0087 code which means the engine isn't getting enough high-pressure fuel. If you happen to have a set of gauges, you'll notice the rail pressure isn't nearly as high as it normally is, and if you investigate further by datalogging desired versus actual fuel rail pressure with a scan tool like EFI Live, you'll notice a large difference between the two. In my case, the truck was asking for just over 26,000 PSI of fuel, but by the time the engine got to 3,300 RPM the actual rail pressure dropped to 13,000 PSI, which was HALF of what the ECM was commanding, severely limiting horsepower. This particular log was taken with the DSP switch in the 3rd tune which produces an additional 90 hp over stock, and the problem becomes much more frequent on the higher settings, since the fuel demand goes up with the hotter tunes.

If you experience a loss of rail pressure, there are a few possible causes. First, these symptoms can indicate a clogged fuel filter. Many first-time diesel truck owners think you need to change a diesel filter at the same interval as a gas engine, but in reality, it needs to be changed much sooner. While a gas engine might make it 75k before a filter change, it should be common practice to change a Duramax fuel filter every 10,000 miles. As the filter clogs with dirt and debris, fuel flow is impeded, and the pump can't generate the desired pressure. So, to troubleshoot, simply swap out the old filter for a new one and see if the problem goes away. In my case, it didn't make any difference in the low rail pressure, so I had to keep looking.

Next on the checklist is to thoroughly examine the fuel lines that run from the tank to the engine. They are made partly from aluminum hard lines, and partly from nylon reinforced rubber hose. There are few places where the rubber hose makes a bend, specifically over the driver's side valve cover, another near the transmission underneath the truck, and a few more near the fuel tank. Pay special attention to the rubber hose around the bends, because the suction from the injection pump can cause the hose to collapse and pinch off the flow of fuel. You may have to remove the plastic corrugated protective sleeve from the hose, but if you are thorough, you might be able to spot a collapsed section. If so, it's not a huge deal to replace the line, but in my case, everything was A.O.K. which meant my low rail pressure was still going to be an issue.

If you remember the basic fuel system anatomy, you'll recall there is a fuel pressure relief valve in the rail, and occasionally it can open prematurely and cause low rail pressure. The one way to spot an failing pressure relief valve it to fire up your scan tool, recreate the symptom, and record another data log. If you see a sharp sudden drop in rail pressure rather than a gradual decline, your valve is popping off too soon, and it's an easy fix. Rather than replacing the valve with another, just swap the valve for a pressure relief plug from ATS, and you'll never have to worry about the valve opening up again. This will work for a race truck, but also on a truck which spends its whole life on the street.

For myself, and many Duramax owners alike, none of those fixes would solve the curious case of the disappearing fuel rail pressure, but I knew there was one thing to blame (or rather a lack of a thing). Remember that one part GM omitted from their fuel system? Well, as it turns out, that missing pump does cause a few problems, which is why a lift pump is so crucial.

Several Solutions

By installing an electric pump near the tank and pushing around 10 psi of fuel to the injection pump, you take a lot of stress away from the CP3 (or 4) and allow it to focus on its main job of creating high pressure fuel, and that one simple change can have multiple positive side effects. As usual, you do have a few choices on how to get a fuel pump into the mix, and the simplest and most cost effective is the PPE Lift Pump. It installs just outside the tank, bolts to the frame rail, intercepts the stock suction line, and pushes the fuel on its way to the engine. Your stock filter head is retained, and no other modifications to the tank or rest of the fuel system are required. Just plumb it in, wire it up, and your fuel system will now be working to its full potential with no drop in rail pressure under load. The pump flows 160 gallons of fuel per hour which will keep up with the most demanding injection pump and performance driving situation. One elegant pump solution which is only available for the 2011+ LML trucks (for now) is the Fleece PowerFlo in-tank lift pump assembly. It's by far the easiest to install and quietest lift pump out there, since the pumps sit inside the fuel tank which insulates the noise. There are ZERO modifications required to the tank, lines, or fuel filler neck, and it will support 800-wheel horsepower. Plus, the OE design of the bucket the pumps sit in ensure the suction side will always be submerged, even if the tank is nearly empty.

While fixing the fuel supply is a good start, a simple standalone lift pump does nothing to increase the filtration, and the fuel oil we love is pretty nasty stuff which often contains dirt, water, and other contaminants like air bubbles. The stock filter/water separator on a Duramax will remove particles down to about 10 microns in size, does an OK job of removing water, but does nothing at all for the air that collects in the system. If you are running a lift pump and want cleaner fuel, you can swap to a larger and more efficient Caterpillar 1R-0750 fuel filter which removes particles as small as 2 microns. All you need to install it is an adapter kit from Sinister Diesel, but the Cat filter only addresses one of the three contaminants in your fuel.

By installing a FASS Titanium Signature Series pump you'll solve all the problems with a Duramax fuel system in one fell swoop. The high efficiency FASS filters will now remove dirt particles down to 2 microns in size, the water separator takes out 99.96% of the water from the fuel, and the unique design of the pump also gets rid of any air that might be trapped, sending nothing but the purest fuel up to your injection pump and injectors. Also, because of the way the FASS return system works, the fuel in the tank is constantly being cycled through the filters and will get cleaned several times, which helps your fuel system last a very long time. Of course, the pump will support more horsepower than stock, but the enhanced filtration and refining of the fuel will lead to a smoother idle, longer injector and pump life, and even improves emissions output. Depending on your needs, you can choose a pump which flows anywhere from 95 gallons per hours (less than 600hp), all the way up to a massive 290 gallons per hour which will support 1,500hp by itself. And the best part is, even the larger pumps are able to operate in low fuel demand conditions, which means your 1,500hp truck can still be used as a daily driver and sit in traffic all day long (if you want to, that is).

Other Upgrades

You can install a FASS pump with the stock fuel suction line coming from the tank, but there are a few other upgrades you should install at the same time which will make for a more well-rounded and better working fuel system. A fuel tank sump does two things: allows a larger diameter suction tube to feed more volume to the lift pump and ensures the suction tube is always submerged in fuel. Also, since the filters on the FASS system perform better in every way, there's no sense to keep the stock filter mounted up on the engine. A fuel filter delete kit will allow you to get rid of the bulky and expensive stock filter, and also gives you a location to mount a fuel pressure gauge sending unit.

Installation

If you know me, you'll know I'm an advocate for people learning how to install parts on their own, and a FASS system is a great place to start if you are just getting into diesel performance. All you need are basic hand tools and a drill, and you can complete the installation in one day. On my 2008 LMM Duramax, I chose to install a Titanium Signature Series 165, along with the FASS Sump/Suction Tube Kit which allowed me to pull fuel from the bottom of the tank with a high flow ½" line without running any rubber hoses along the bottom of the tank, which was important on a lowered 2wd street truck. Another benefit of their bulkhead fitting was it provided a port to run the FASS Mass Flow Return line into the tank without having to slice into the filler neck. The FASS kit does come with an adjustable bracket to mount the pump from a bed bolt, but I chose to run a Wehrli Custom Fab bracket that places the pump on the inside of the frame, far away from any debris or water from the tires, and it keeps the pump hidden for a stealth look. The very first step to install a FASS was to bolt on the bracket and get the pump mounted, and the next step was to drill a few holes in the tank, but for easier access, I first removed the bed of the truck.

Once the fuel level sending unit/basket was removed from the tank, I marked and drilled a pilot hole through the bottom of the tank and allowed the fuel to drain into a clean 5-gallon bucket. Just make sure the hole isn't directly below the sending unit. Then, the hole is enlarged to 2-3/4" with a hole saw. Finally, using the sump as a guide, a series of 1/4″ holes are drilled around the perimeter, and some screws hold everything in place. Atop the tank, another hole is drilled, and the bulkhead fitting is installed with a nut holding it from the backside. Inside of the tank, the suction tube is connected between the sump and bulkhead. Now, it's time to route the 1/2" fuel lines between the tank and the pump, and from the pump output to the stock suction line which now receives pressure. If the lines run near any sharp edges which might rub against them, it's good practice to protect the lines with some 5/8" heater hose which has been cut lengthwise and slid over the fuel line. Once the plumbing is all done and hoses secured, the stock sending unit goes back in, the return line re-attached, and the bed can go back onto the truck. The very last step of the install is to attach the provided wiring harness to the battery and the fuse block, mount the relay, and run the wires to the pump. Once everything is connected, prime the pump, check for leaks, and enjoy.

Totally Worth It

Once all the hard work is done, what is the result? For me, a subsequent data log with EFI LIVE confirmed exactly what the butt dyno suggested. Even with the DSP switch cranked up to four or five, the rail pressure stayed exactly where the computer wanted it to be, the acceleration was restored, and of course all the side effects of a smoother and more efficient running engine could be felt as well, making for one very satisfied customer. The mystery of why GM never installed a lift pump may never be solved, but at least they acknowledged the problem with the introduction of the L5P trucks in 2017. Now, all we need to figure out is who killed Jimmy Hoffa…

Source: https://www.dieselpowerproducts.com/blog/why-the-duramax-never-had-a-lift-pump-and-why-it-shouldve/

Post a Comment for "05 Duramax Cp3 Pump Lift Pump Bad Can I Just Use a New Lift Pump to Feed It"